Our

Infrastructure

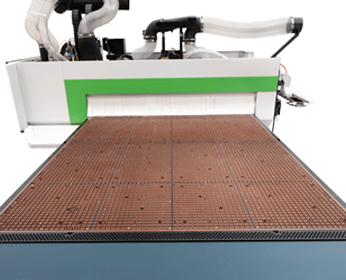

- We have invested into the state of the art Italian machines for wood working and painting areas with the production capacity of around 5000 sft per shift.

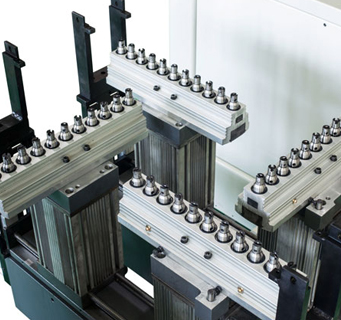

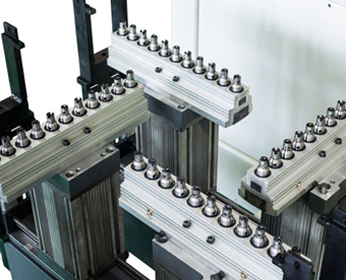

- Various processes like sizing of boards, edge banding the cut/ sawn edges, boring for insertion of dowels & fitting, sanding, polishing and painting are all done in automated machines with high precision.

- Our machines have the flexibility to manufacture components for a range of panel based products including kitchens, office furniture, computer tables, TV cabinets, wardrobes etc., and other Solid Wood based products.

- Our design and manufacturing software is effectively used for easy design, management and effective programming of cabinet designs (wall units, fixed shelves, adjustable shelves, doors, drawers and individual tops) and door designs (door element design, core panel doors and routed doors).

Machinery

We provide high quality polishing and wood coating services at our state-of-the-art facility. We are equipped with a 3 meter Dry Paint Booth with automated blower/dryer kept in a pressurised room for dust free spraying and drying. We offer several finishes like Duco, Melamine, PU, Polyester, and Acrylic finish on MDF, Veneer and other Hardwoods from dead Matt to high gloss levels.

Our Range of Finishes

Prelaminated Finish

Particle Board, MDF, HDF, HDHMR, UV Panels and MR Ply

Post Laminated Finishes

Base Material

Particle Board, MDF, HDF, HDHMR and UV Panels, MR Ply, BWR Ply and BWP Ply

Finishes

Suede(SF), High Gloss Laminates, Designer Laminates, Textured Laminates, Laminates with Chamfering and Buffability, & Acrylic Sheets

Polished Finishes

Base Material

MDF, HDF, HDHMR Veneers, Solid Woods – Rubber wood, teak wood, etc

Finishes

Matt, Glossy and High

PU (Polyurethane) –solvent and water based, Acrylic , Polyester